Feb 9,2024

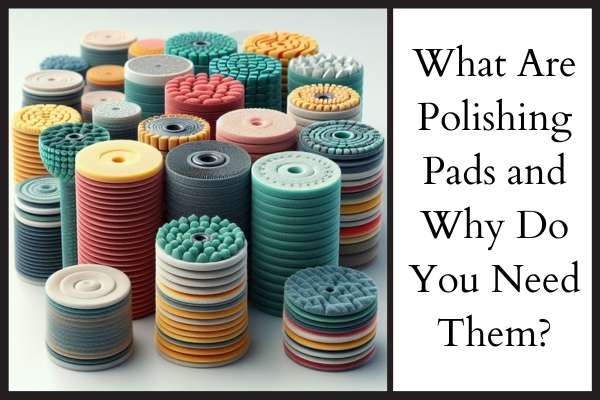

In the ever-evolving world of detailing, polishing pads have become an indispensable tool for enthusiasts and professionals alike. If you're wondering, "What are polishing pads, and why do I need them?" you're in the right place. This comprehensive guide will not only demystify the purpose of these pads but also highlight their crucial role in achieving a flawless finish for your vehicles or other surfaces.

Polishing pads, often overlooked in the grand scheme of detailing, are intricate tools designed to enhance the visual appeal of surfaces. Their composition, consisting of a foam layer, Velcro backing, and a specialized face material, works harmoniously to deliver impeccable results.

1. Foam Layer: The foam layer's density dictates the pad's firmness, influencing its performance during the polishing process. Softer foams are ideal for light corrections, while denser foams excel in tackling more stubborn imperfections.

2. Velcro Backing: The Velcro backing ensures a secure connection between the pad and the polishing machine. This not only simplifies the application process but also guarantees stability during operation.

3. Face Material: The face material, crafted from microfiber or foam, is the point of contact with the surface. Its texture and composition play a pivotal role in determining the level of abrasiveness and the pad's overall effectiveness.

Now that we've unraveled the mystery behind their construction, let's explore why polishing pads are a game-changer in automotive detailing.

Polishing pads serve as the frontline soldiers in the battle against imperfections. When paired with a suitable polishing compound, they efficiently remove swirl marks, scratches, and oxidation, unveiling a vibrant and flawless paint finish.

The beauty of polishing pads lies in their adaptability. From cutting pads designed for heavy correction to finishing pads for the final touch, there's a pad tailored to every detailing need. This versatility extends beyond automobiles, making them indispensable for various surfaces like glass, plastic, and metal.

Gone are the days of manual labor-intensive polishing. In tandem with high-quality machines, polishing pads significantly reduce the time and effort required to achieve professional-level results. This not only enhances efficiency but also makes the detailing process more accessible for enthusiasts.

Polishing pads contribute to more than just aesthetic improvements. By creating a smoother surface, they act as a barrier against dirt and contaminants. This not only preserves the paint's integrity but also ensures long-term protection, extending the life of the surface being treated.

Selecting the ideal polishing pad involves a nuanced approach, considering factors such as the type of imperfections, paint hardness, and desired cut level.

1. Type of Imperfections: Identify the specific issues you're addressing—light swirls, deep scratches, or oxidation. Different pads cater to distinct problems, so choose accordingly.

2. Paint Hardness: Consider the hardness of the paint on the surface. Softer paints may require softer pads to avoid unnecessary abrasion, while harder paints benefit from more aggressive pads.

3. Desired Level of Cut: Gauge how much correction is needed. If you're aiming for a subtle improvement, a finishing pad is suitable, while deeper imperfections may necessitate a cutting pad.

In conclusion, polishing pads are the unsung heroes of the detailing world. They offer a precise and efficient solution to achieving a flawless finish. Whether you're a seasoned professional or a passionate DIY enthusiast, incorporating the right polishing pad into your arsenal is a game-changer.

Investing in quality pads and mastering their use is a commitment to your prized possessions' longevity and aesthetic appeal. So, the next time you embark on a detailing journey, remember that behind every impeccable shine is a reliable polishing pad, quietly doing its job to perfection.